machining surface finish callout

For instance when manufactured products possess smooth surfaces they resist wear and tear better than finished parts with rougher surfaces because friction levels remain lower. The surface finish can affect several abilities of the product part to resist wear and tear.

The Basics Of Surface Finish Gd T Basics

You can select the face in a part assembly or drawing document.

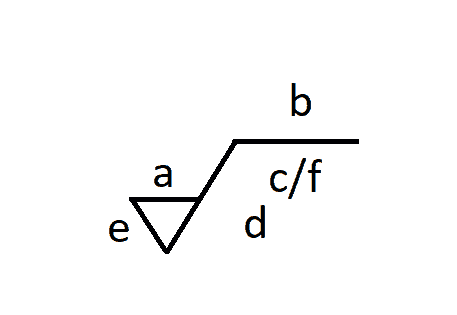

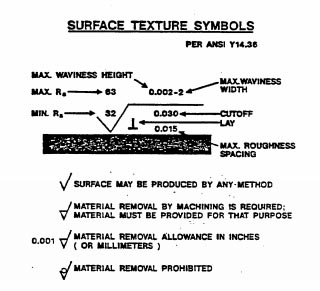

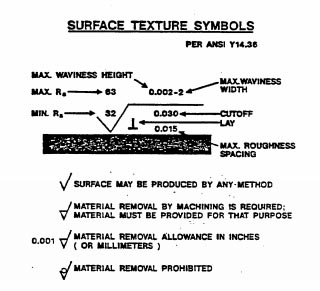

. It is the result of the manufacturing processes used and can have a major impact on the function aesthetics and durability of the final product. Now depending on the application being manufactured certain roughness. There are many variations of the surface texture symbol but most often it is used with a microinch or micrometer value callout that specifies the roughness of a surface.

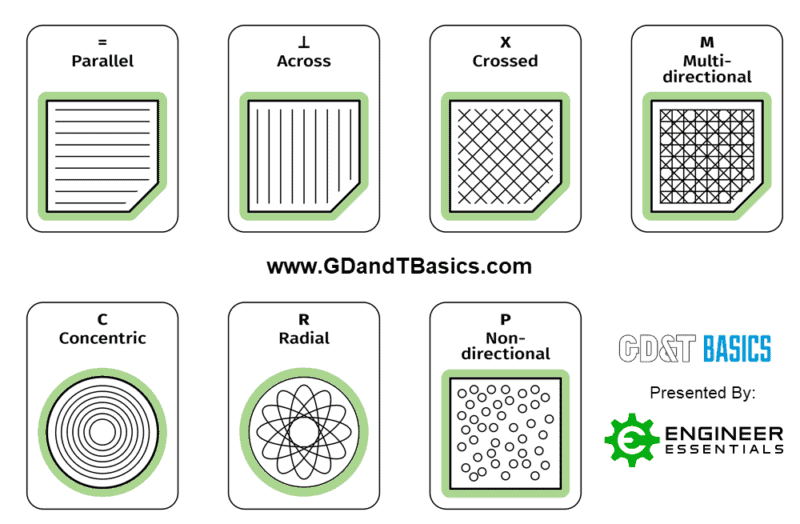

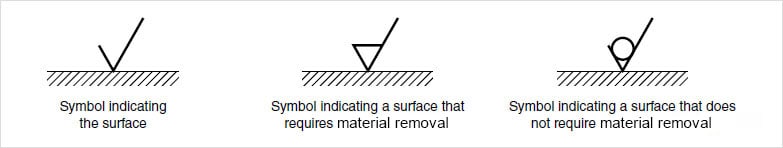

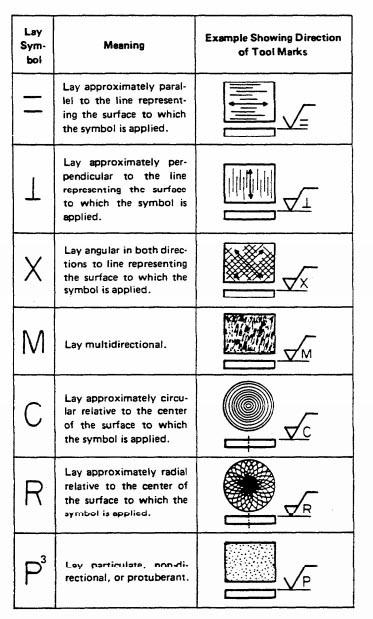

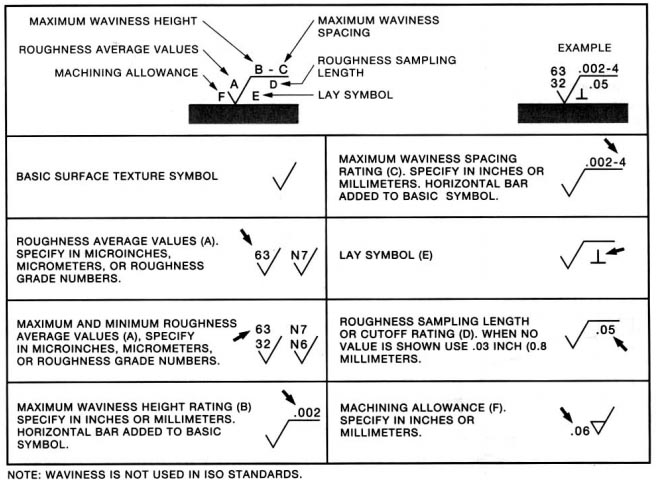

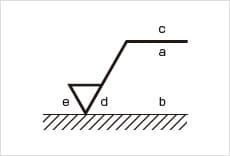

The contact method is more common and involves the use of a stylus. If it is a turned surface then the C probably denotes a circular lay to the finish. The tick symbol is placed on the surface or an extension drawn to it.

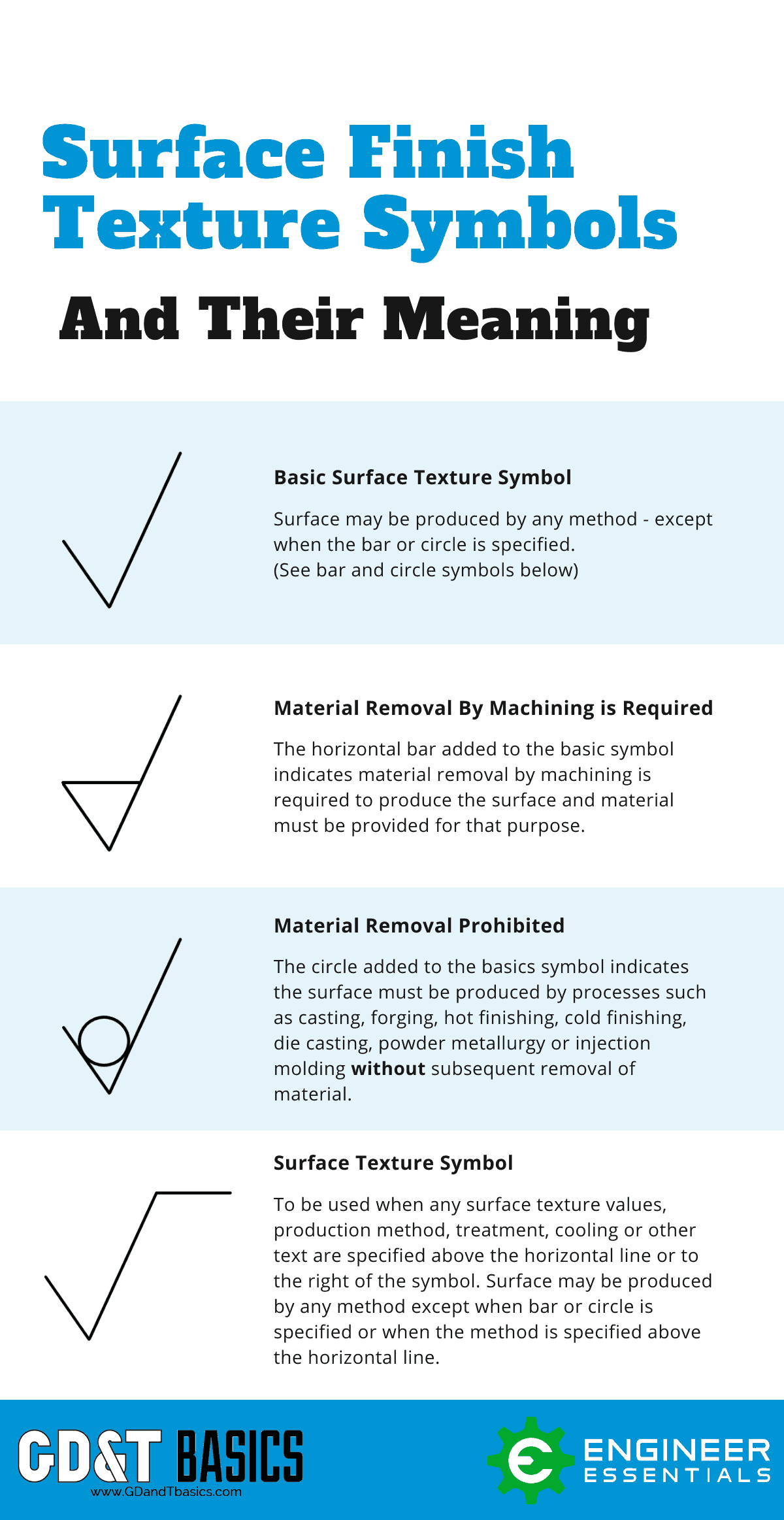

The tick symbol is placed on the surface or an extension drawn to it. The details in iso surface finish standards relate to surfaces produced by abrading casting coating cutting etching plastic deformation sintering wear erosion and some other methods. You can specify the surface texture of a part face by using a surface finish symbol.

If its an inch print then it woulod be 82 microinches which would need to be a ground surface. For ISO and related drafting standards you can display surface finish symbols per 2002 standards. Roughness consists of surface irregularities which result from the various machining process.

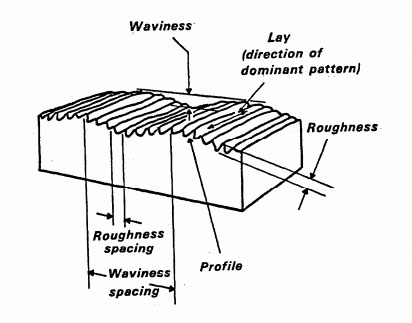

Machining surface finish callout. Machining surface finish influences the quality durability and performance of manufactured parts and components. These irregularities combine to form surface texture.

Weve picked up a lot of fundamentals in prior chapters. It is measured in millimeters or microns or microinches. A symbol for defining the surface finish of a part.

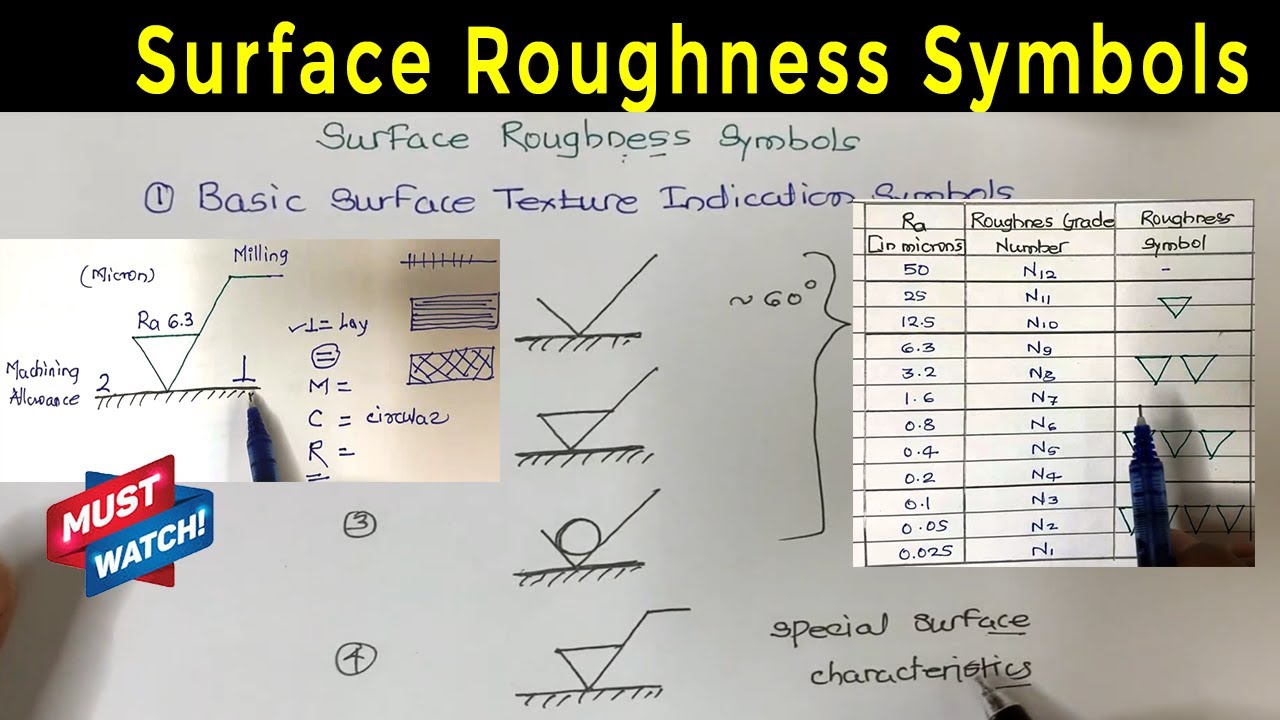

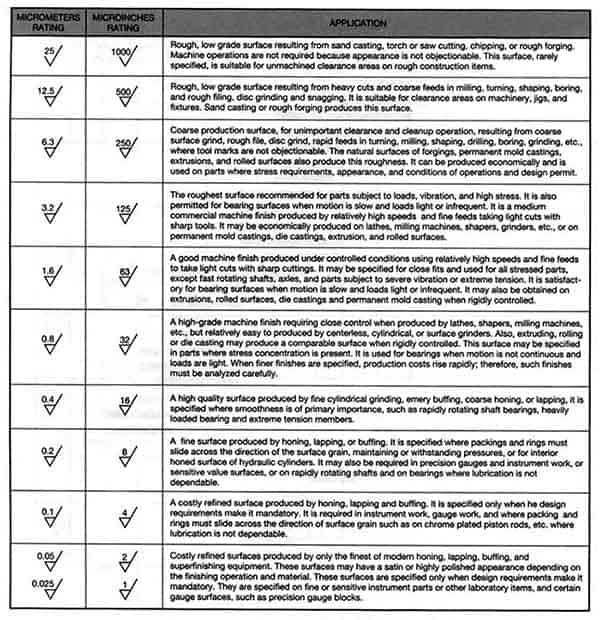

Machining N9 250 63 N10 500 125 Rough Machining N11 1000 25 N12 2000. It is the height of the irregularities with respect to a reference line. Surface Roughness Terminology.

However achieving precise surface roughness seems not very easy and may be costly. There are two ways to measure the surface finish. Finish Symbol N Finish R a μinch R a μm Super finishing.

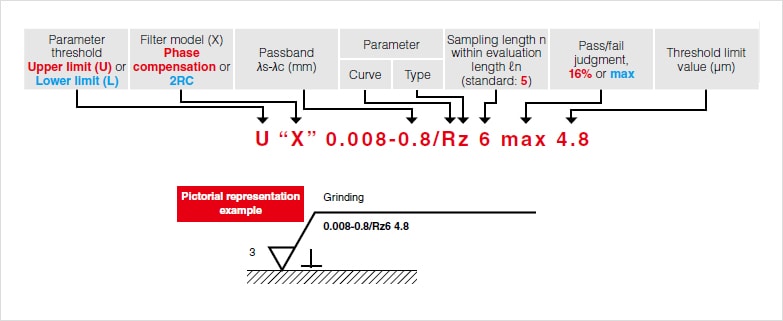

Therefore it is crucial to evaluate the durability and effectiveness of the product during usage. For example 16 63 rms 32 125 rms and 63 250 rms. Passband or sampling length and surface texture parameter symbol and value.

Measuring surface finish is also referred to as surface metrology. N1 1 0025 Lapping. And for metric triangle callouts you can approximate one triangle 250 finish two triangles 125 finish and three triangles 32 to 63 finish.

Surface finish symbols are formed by combining the Symbol and Lay Direction direction of lay. This surface roughness indication method pictorially displays information such as the surface roughness value cutoff value sampling length machining method crease direction symbol and surface waviness on the surface indication symbol as shown below. It is an important part of many fields and is mostly known for the CNC machining of precision parts and assemblages.

Contact and non-contact methods. Symbols Used In GDT Callouts Basic Dimensions Basic dimensions represent a theoretically perfect feature or size. A callout on a drawing of a minimum surface finish is normally to insure buddy machining it who is under the gun isnt going to finish it with a 020rev federate on looser specs.

If the part is metric then the 82 most likely means an 82 micron Ra finish. Surface finish is the process of creating the desired surface roughness on a fabricated part. Surface finishing plays a key role in custom machining for determining how a product reacts with its immediate environment.

DennisP Mechanical 21 Jun 07 0457. Ones rms is to mentally multiply the metric value by 40. An easy way to convert metric surface call outs to standard US.

Surface Finish Destiny Tool Surface Texture Callout Symbol And Brief Explanation Of Symbols Download Scientific Diagram The. Surface finish specification and comparison.

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Surface Roughness Symbol In Drawings Mechanical Engineering General Discussion Eng Tips

What Is Surface Finish Units Symbols Chart Engineering Choice

The Basics Of Surface Finish Gd T Basics

The Basics Of Surface Finish Gd T Basics

Surface Roughness Symbol In Drawings Mechanical Engineering General Discussion Eng Tips

Understanding Surface Roughness Symbols Introduction To Roughness Keyence America

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Texture Symbols Drafting Gd T Simpliengineering

Surface Finish Texture Symbols Drafting Gd T Simpliengineering

Iso Surface Roughness Symbols Terminology

Solved Iso Surface Roughness Symbol Missing Roughness Autodesk Community Fusion 360

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Understanding Surface Roughness Symbols Introduction To Roughness Keyence America

The Basics Of Surface Finish Gd T Basics

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Understanding Surface Roughness Symbols Introduction To Roughness Keyence America